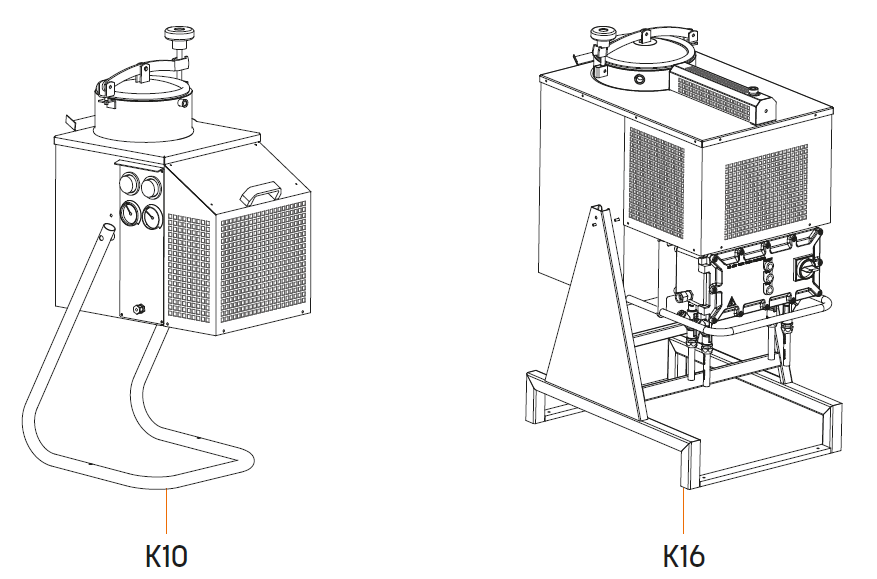

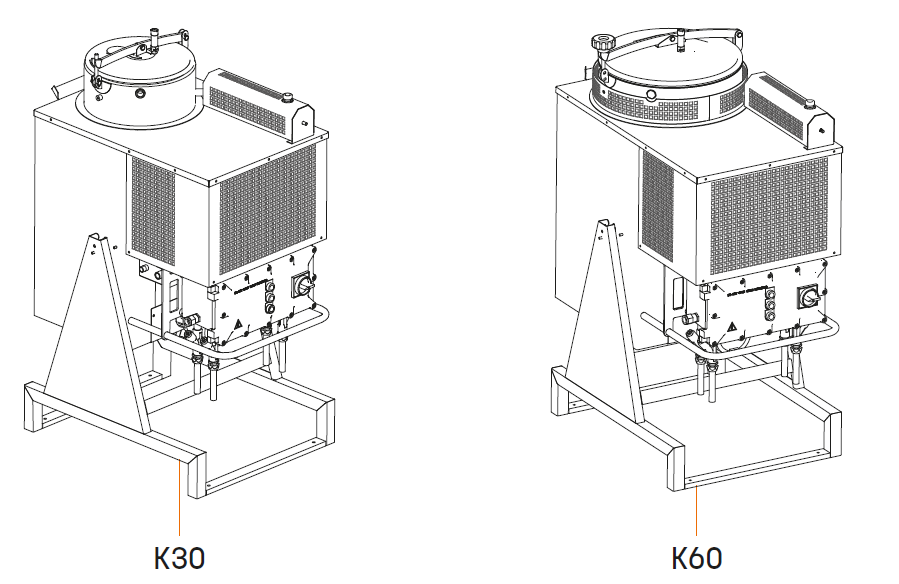

Smart Series Distillation Systems

Designed for versatility and ease of use, the Smart series offers manual operation with ATEX certification. It’s perfect for smaller-scale operations requiring reliable solvent recovery, featuring analog programming and vacuum distillation.

The Smart series provides efficient and safe distillation solutions with manual operation and simple controls, designed to meet the needs of small to medium-sized operations. These units offer reliable performance and compliance with safety standards, making them ideal for various industrial applications.

Key Features:

- Daily Productivity: Ranges from 10 to 180 liters per day, suitable for small to medium-sized operations.

- Manual Operation: Simple and straightforward manual loading and operation.

- Vacuum Distillation: Reduces distillation temperatures to enhance safety and efficiency.

- ATEX Certification: Ensures safe operation in potentially explosive atmospheres (ATEX Zone 1).

- Analogue Programming: Easy-to-use analogue controls for setting distillation parameters.

- Distillation Bags: Facilitate easy discharge of sludge and keep the boiling chamber clean.

Technical Details:

Applications:

For Printing Presses:

- Equipped with an air-cooled, high-performance vapor condenser.

- Features a vacuum generator to reduce the distillation temperature and prevent exothermic reactions with nitrocellulose-based inks.

- Incorporates a containment tank to manage accidental overflows.

- Distillation bags for easy sludge discharge and boiling chamber maintenance.

For Photopolymer Production:

- Air-cooled, high-performance vapor condenser.

- Utilizes a vacuum generator to manage distillation temperatures, particularly for ecological solvents with high boiling points.

- Containment tank for safety and compliance.

- Option to use distillation bags for efficient sludge management.

- Stainless steel condenser available for handling chlorinated solvents.