PRINT YOUR CYLINDERS CLEAN!

The anilox roll is a critical and often overlooked element in flexo print quality.

As anilox rolls get dirty or worn, print density goes down. This leads to more press down-time and material waste, two of the largest cost components in a typical printing plant.

Spring has developed a full offering to help printers, particularly corrugated board converters, keep their anilox rolls in optimum conditions and their printing presses running at full capacity.

Flexi-Lox is an innovative technology that allows printers to clean their anilox rolls without removing them from the press- and while they are printing on other stations.

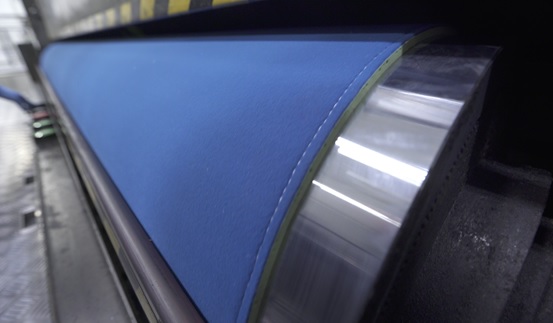

The Flexi-Lox anilox cleaning systems consists of a Micro Fiber cleaning blanket integrated on a dimensionally stable compressible foam. Flexi-Lox blankets mount like traditional plates using a combination of locking strip and tension bands.

The Flexi-Lox blanket works in combination with the Powerwash cleaning solutions to “print cylinders clean”.

- Repeatable print quality

- Reduced press set-up

- Higher ink densities; lower ink consumption

In addition to the Flexi-Lox system, Spring has a series of cleaning solutions for:

- Ultrasonic cleaning units

- Parts washers

- Manual cleaning with SoftClean

- In-line photopolymer plate cleaning